Taulman Nylon 645 | Printing With Nylon

One of the most significant challenges with 3D printing technology is finding a suitable filament to ensure your project succeeds. With plenty of options to choose from – such as PLA, ABS, and carbon fiber – 3D printing enthusiasts are starting to turn their attention to nylon. Could it be the right filament for you?

Well, there’s no better way to test it than with Taulman Nylon 645 – one of the world’s most popular 3D printing materials. Whether you’re a 25-year-old hobbyist or a multi-billion dollar company, we will detail everything you need to know about this nylon filament before trusting it with your next project.

Printing With Nylon

Printing with nylon filament might just be one of the hardest challenges you will face when 3D printing. But don’t worry! It will be easy once you have everything tweaked to perfection, especially with the Taulman Nylon.

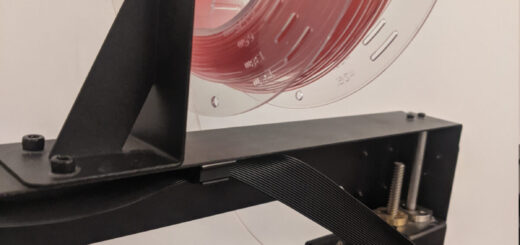

One of the most important tips to remember is that nylon needs to be very (and I mean VERY) dry when printing. Most nylon filament will be unusable for printing if left in a normal indoor climate for a few hours and will need to be dried again.

We recommend that you store your nylon filament in an airtight box together with some type of moisture absorber.

For best results, use a filament dryer while printing to avoid moisture ruining your print halfway through. Been there, done that.

What is Taulman Nylon 645?

Taulman Nylon 645 is a nylon co-polymer filament manufactured by Taulman 3D – a leader in the filament industry. It’s touted for its high-strength properties, high optical clarity, transparency/translucency, and impressive thread-to-thread bonding, allowing for a durable build with impeccable bridging performances.

Taulman Nylon 645 vs. Traditional Nylon

Taulman Nylon 645 addresses several concerns regarding traditional nylon filaments. For example, many nylon projects failed in the past because of the high temperatures required and lack of compression in 3D printers. With Taulman Nylon 645, the standard material chain is modified to allow for greater bonding.

Not only that, but Taulman Nylon 645 has a greater resistance to chemical degradation (compared to traditional nylon) – allowing users to print 3D molds and print in harsh environments. It also provides a much smoother surface finish, ensuring a quality build ready for immediate distribution.

Taulman Nylon 645 vs. ABS

Acrylonitrile butadiene styrene, also known as ABS, is one of the most popular 3D printing materials today, but many people are starting to prefer Taulman Nylon 645. Here are some of the most prominent reasons why:

- Strength – many users are surprised at how strong Taulman Nylon 645 prints are, especially compared to their ABS counterparts.

- Weight – Taulman 645 strikes a healthy balance between being stronger, yet lighter than other materials (including ABS).

- Pliability – the flexibility and elasticity of Taulman Nylon 645 opens the door to many more opportunities when 3D printing, such as reducing the need for filing, cutting, and sanding.

- Surface – thanks to the slippery surface of Taulman 645 prints, certain parts (like ball bearings) won’t require lubrication, and threaded holes won’t delaminate under pressure.

While Taulman Nylon 645 isn’t FDA-approved (like ABS), the primary reason is that the approval process is a “very expensive undertaking”, according to Taulman 3D’s official website.

Taulman Nylon 645 Safety

Taulman 645 Nylon is a safe and effective filament to use when 3D printing, but you don’t need to take our word for it.

- 645 Nylon doesn’t contain any additives or chemicals listed in the REACH Directive and complies with The European Chemicals Agency (ECHA) and the European Union (EU) standards

- 645 Nylon doesn’t contain any hazardous substances listed under the Comprehensive Environmental Response Compensation and Liability Act (CERCLA)

- Nylon 645 doesn’t contain any chemicals listed in the Superfund Amendments and Reauthorization Act of 1986

- Nylon 645 doesn’t contain any pollutants under the Clean Water Act

Nylon 645 also complies with all US state regulations – including Proposition 65 in California and applicable state right-to-know regulations.

Technical Specifications

Customers should know exactly what they’re getting before they purchase a new filament for 3D printing. With that said, here’s a look at the technical specifications for Taulman Nylon 645:

- Printing Temperature – 250-255C

- Melting Temperature – 217C

- Tg Glass Transition – 52C

- Pyrolysis (Thermal Degradation) – 350-360C

- Print Bed Temperature – 30-65C

- Optimal Bed Surface – Garolite

- Tensile Strength (PSI) – 5,188

- Shrinkage (in) – 0.0062

- Opacity – 45%

- CNC Coolant – Forced Air Only

- Normal Diameters – 1.75mm and 2.85mm (3mm)

- Nozzle – Any Size

- Water Absorption – 3.09%

- UV – there are no UV inhibitors

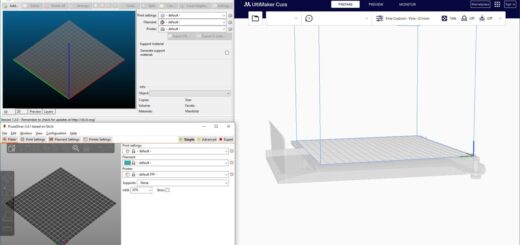

Taulman 645 can be used in a wide variety of 3D printers, including Makerbot Replicator, PrintrBot, Ultimaker, MakeMendel, BukoBot, Gigabot, Mendel, Lulzbot, inDimension3, RepRap, Cerberus, UP, Afinia, Robot Factory, Power Wasp, RoboBot, Bits from Bites, Rostock, and Makergear printers.

Taulman Nylon Usage Tips

Every type of 3D printing material requires a unique printing environment (humidity, printing temperature, print bed temperature, bed surface, etc.), and Taulman Nylon 645 is no different. Here’s a look at some of the most prominent usage tips when using Nylon 645:

- Make sure that the filament is dry. (I mean really dry)

- Use a raft when printing with nylon to avoid an ugly first layer

- When storing your nylon, keep it away from moisture and in a vacuum bag or sealed container

- If you’re having a hard time bonding layers together, increase the extruder temperature by 5C until you find the sweet spot

- While some people prefer to print on blue painter’s tape, this process can be frustrating

- Try printing nylon with an extrusion temperature of ~240C and a bed temperature of ~80C.

- Don’t forget to turn up the retraction on the printer to prevent your print from looking stringy

FAQs About Taulman Nylon 645

- Can you print in high-resolution with Taulman Nylon 645? Yes, the Taulman 645 filament can be used for high-resolution prints.

- Will I need to change any settings in my slicing software before using Taulman 645? While it’s ready for use after installation, some users adjusted their idler tension and increased their retraction distance to prevent trailing threads.

- How can I get my prints to stick to the platform? Most users found success by coating a clean glass with PVA (Elmers Glue All) and heating the glass to 45-50C.

- ABS produces a strong odor when printing – is that true with Taulman 645, too? Unlike ABS, Taulman Nylon 645 produces minimal odors, and ventilation isn’t as necessary.

- Is it easy to change back to ABS when needed? Of course! Most users report no issues going back and forth between ABS and 645 – just ensure your settings are correct!

- What chemicals should I avoid when using Taulman Nylon 645? It’s best to avoid any strong acids, such as chlorine or bromine, as they could weaken the build.