PolyLite PETG | Review

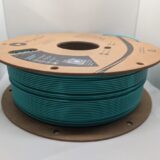

For many mechanical projects, looking good and being functional are equally important. The Polymaker PolyLite PETG 1.75mm filament in the color teal has emerged as a favorite for those seeking a visually pleasant part that can withstand mechanical and thermal stresses over a long period.

PolyLite PETG filaments sit in the middle of the pricing range and have developed a reputation for being reliable choices for projects where both form and function matter. These materials are sensitive to operational settings and can frustrate newcomers. As we discuss here, those with the patience to tune their printing settings are rewarded with stylish parts ready for many applications.

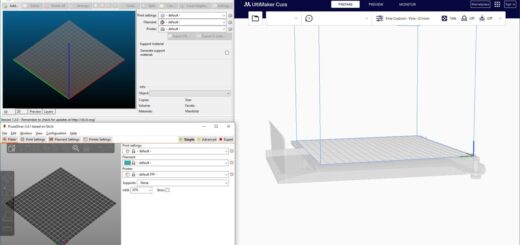

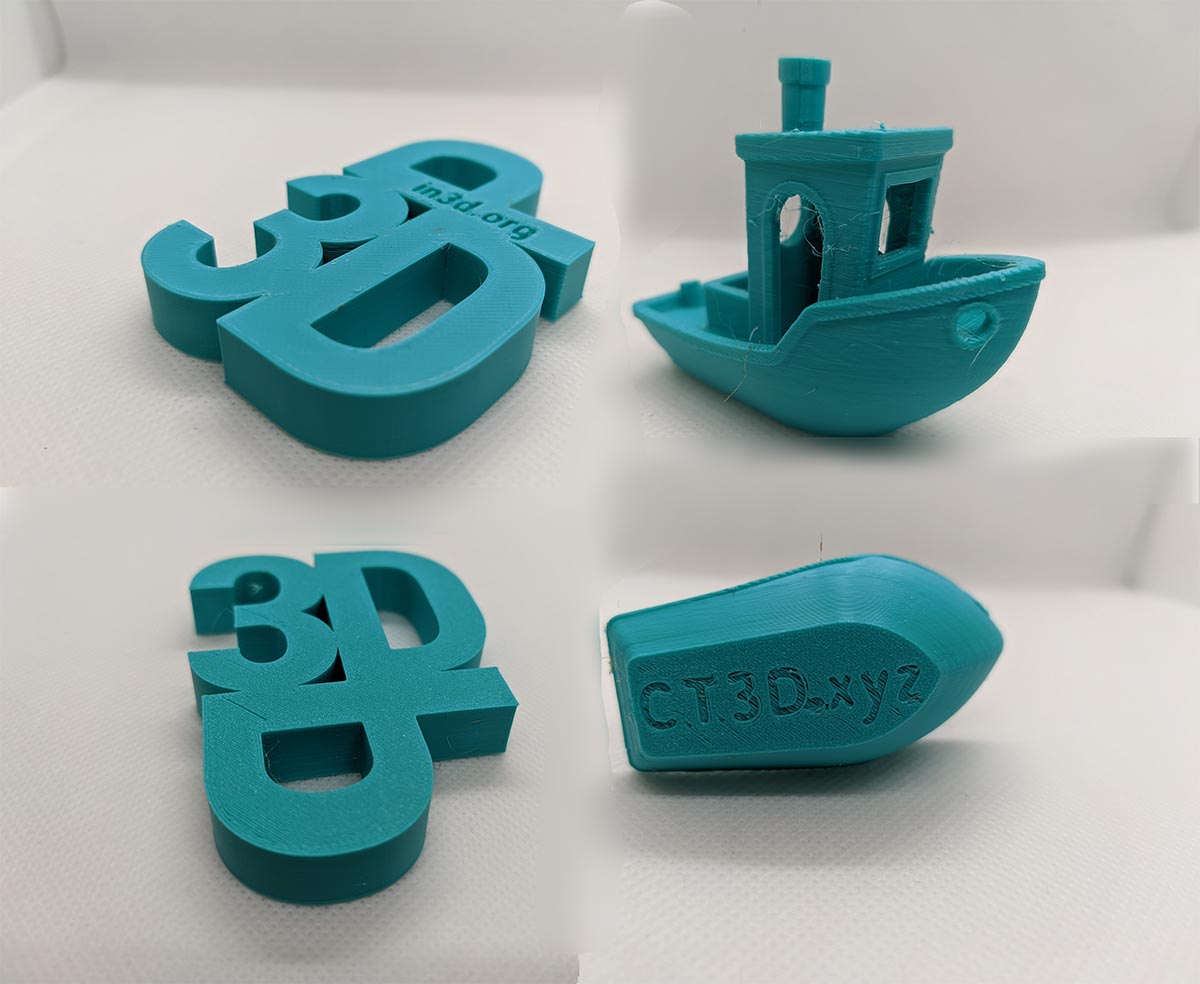

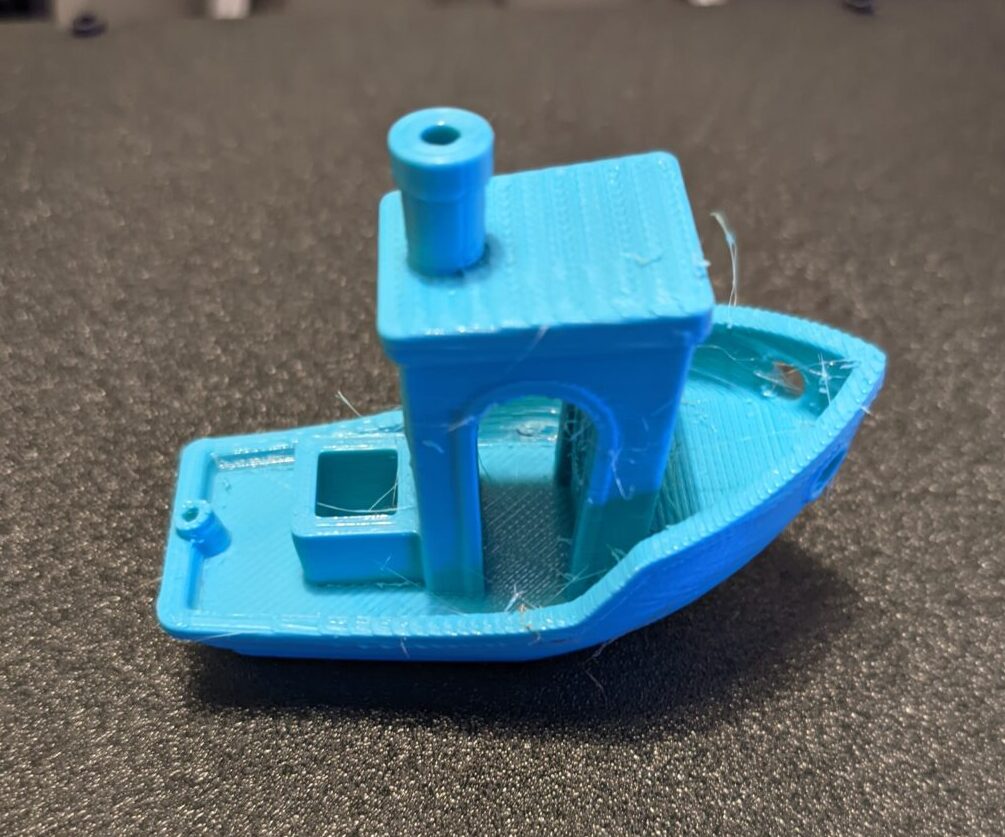

Print Test

Our first test came out a little bit stringy but overall nice quality considering the type of material.

Print Temperature: 240°C

Print Speed: 40mm/s

Layer Height: 0.2mm

PolyLite PETG 1.75mm Filament Specifications

These values are the Polymaker operational recommendations for a 0.4 mm nozzle and work with most printers. However, not all equipment is born equal. Prepare for some trial and error to get the right results.

- Nozzle temperature: 230º to 240ºC

- Speed: 30 to 50 mm/s

- Bed temperature: 70º to 80ºC

- Bed Adhesion Technique: Brim

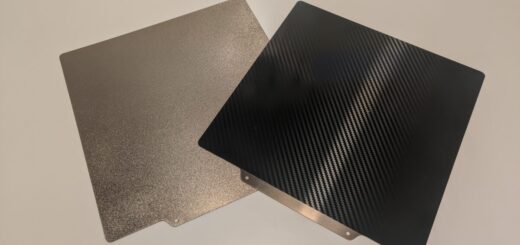

- Bed Surface: Glass with glue treatment, BuildTak, or similar specialized surfaces

- Cooling fan: Off or set to 20%

- Layer height: 0.1

- Number of Layers/Outlines:

- Top and Bottom: 4

- Shell: 3

- Raft Separation: 0.14 mm

- Retraction: 1 mm

- Drying: 8 hours at 70ºC

The PolyLite PETG 1.75mm teal filament guarantees a diameter tolerance of 0.04 mm in 99.9% of cases, with 70% of prints over or under 0.01 mm of the specified dimensions. Tests with different-sized products show the weight tolerance consistently falls between 2% and 3.5%. The precision is slightly above the market average.

This PETG filament offers value for prints focused on aesthetics due to its weak mechanical properties, high precision, and unique color.

PolyLite PETG Specifications

The properties of PolyLite PETG 1.75mm filament stay the same across different colors, so feel free to use these values as references for other variations.

- Density (for T = 23ºC): 1.25 g/cm^3

PolyLite PETG 1.75mm Mechanical Properties:

- Young Modulus: 1472 MPa (tolerance of +/- 270 MPa)

- Tensile Strength: 31.9 MPa (+/- 1.1 MPa)

- Fracture Strain: 6.8% (+/- 0.9%)

- Bending Modulus: 1174 MPa (+/- 64)

- Bending Strength: 53.7 MPa (+/- 2.4)

PolyLite PETG 1.75mm Thermal Properties:

- Glass Transition Temperature: 81 ºC

- Vicat Softening Temperature: 84 ºC

- Melting Index (2.16 kg of filament at 240ºC): 10.8 g/10 min

- Heat deflection temperature (delta of 0.34 mm): 74.8ºC under 1.8 MPa of pressure, 78.4ºC under 0.45 MPa

PolyLite PETG 1.75mm Chemical Properties:

- Weak to all types of acids and alkalis

- Resistant to most organic solvents

- Not fire retardant

- Water Absorption: 0.54% after 14 days

Usage Tips

The PolyLite teal 1.75mm PETG filament thrives with an all-metal nozzle. Though recommended temperatures start at 230 ºC, most prints with it turn out best from 240ºC. Some makers like to print as hot as they can without causing bubbling, but this is unorthodox.

Faster printing speeds require more power from the heating element. Once the heating element is at full power, the nozzle will not stay at the target temperature during the process, regardless of the settings.

One workaround is having a higher target temperature than intended. As the hot end cools during prints, it retains enough energy to be within an acceptable range until the end. Overheated PolyLite gets stringy and may clog the nozzle while running too cold might create adhesion problems. This is far from ideal and leads to inconsistent results.

PolyLite teal print does not require layer cooling times, so the fan stays off. If you are unsure, a low setting (20%) takes care of most situations, including models with small cross-sections or short layers. Using higher settings can cause layer adhesion problems.

Start with a clean and level bed to prevent issues with the base ruining an otherwise good print. As with most PETG filaments, the PolyLite 1.75mm in teal works best with a warm glass bed with temperatures starting at 70ºC, with a thin coat of glue or a purpose-built adhesive like BuildTak or GeckoTek to prevent separation issues. Apply the glue and heat the bed until the adhesive is dry before kicking off the printing program.

Check that the nozzle has some clearance from the bed in the program, as PolyLite filaments produce a better base layer and stick better when poured rather than smeared around.

Quality filament and equipment matter, but not even the best materials and tools can save a print if you fail to prepare well.

FAQ

What are the best settings for the PolyLite PETG 1.75mm teal filament?

For most printers and nozzles, the recommended settings by Polymaker work well. Some combinations work better with nozzle temperatures on the higher end of the suggested range to avoid sticking issues. If you struggle, try increments of 5ºC between tests until you reach the sweet spot.

What is the difference between PolyLite PETG and PLA?

PLA filaments are easier to work with during printing (especially at lower temperatures) and are great for decorative projects. The brittle material does not lend itself well to mechanical or thermal demands.

PETG filaments like this teal one are more sensitive to setting mismatches during printing but make up for it with considerably better flexibility, impact, and temperature resistance.

What are the best applications for PolyLite PETG 1.75mm teal filament?

The PolyLite PETG teal filament blends flexibility and resistance to stress and temperature, making it useful in mechanical projects or even household parts that are subject to stress often.

This is not the most flexible, heat-resistant, or toughest filament, but it is among the few to score well across all these properties.

Conclusion

Print Temperature: 240°C

Print Speed: 40mm/s

Layer Height: 0.2mm

The PolyLite PETG 1.75mm teal filament is an all-around option that marries value with many applications. As a PETG filament, this product has balanced thermal and mechanical properties, allowing for its use in functional items with moderate stress levels.

Getting good results requires more finesse with this filament than its PolyLite PLA counterparts. Adhering to the recommended settings and making tweaks based on your equipment and project is enough to bypass most troubles. Should this not work, competitors at Hatchbox have 1.75mm PETG filaments that are slightly more forgiving to work with, but there is no teal option available. We did however find a good looking green filament.